visual

location

Contents

Corporate Social Responsibility

Over the past thirty-plus years, as SAE-A's business has grown, so has its commitment to employees, corporate social responsibility, and the environmental stewardship. These commitments extend across the entire organization?from its corporate headquarters to its manufacturing facilities. The company is a member of each community in which it works. SAE-A invests in its future, not only through the jobs at facilities, but also through pro-social programs extending beyond the company's campuses. From traditional charitable giving to professional training programs; from infrastructure investments to the environment; and from childhood education to public health, SAE-A strives to be an exemplary member of the community. Understanding that no two places are the same, and to best respond to the needs of each community, pro-social programs are designed locally in conjunction with local employees.

From funding a Guatemalan orphanage to supporting the police and fire departments in Nicaragua to providing free sewing classes to the disabled in Vietnam, SAE-A is committed to making a positive impact all around the world. More information about several of our programs follows.

Working with Communities

Global Headquarters in Korea

SAE-A cultivates an appreciation for corporate social responsibility at its headquarters through in-house CSR seminars and providing opportunities to participate in community outreach projects. Employees are eager to give back to the community whether by visiting orphanages and rehabilitation centers or supporting an orchestra of underprivileged students by helping them buy instruments and pay for music lessons.

Indonesia

- SAE-A Indonesia delivers lunch boxes

-

SAE-A Indonesia PT.SJC has been holding a lunch box volunteer event for a local impoverished village from 2011.?The event was attended by both SJC SAE-A employees and local employees. The reason why SAE-A Indonesia’s event is particularly special as the volunteers use the Happy Center, established in partnership with a local volunteer organization, to make fried chicken lunch boxes and to take them to impoverished villages in Tanjung Priok, and Muara Karang.

- Community Support

-

In celebration of Lebaran, the biggest holiday in Indonesia, SAE-A’s Indonesia branch donates aid kits containing clothes to community service centers in Cikumpay and Cijaya near its Indonesian branches for people in need.

In Cilegong, SAE-A partnered with the local government and communities to build a bridge that is helping ease transportation burdens and facilitate economic activities in the community.

SAE-A has worked with the community to build a water reservoir providing clean water families in the area while also helping them save money previously spent on procuring water.

Vietnam

-

In Vietnam, SAE-A sponsors the Tam Binh Shelter and Tam Bihn Orphanage. Located near its Vietnamese facilities, Tam Binh Shelter cares for children born with HIV. Employees from the Vietnam branch visit the shelter and orphanage twice a month to drop off food and clothing donated by employees and the management.

SAE-A local labor union and the Health Department of Thanh Hoa have worked together to provide free anthelmintic medication for employees. The program included training in preventative measures to guard against parasitic infections.

- In July 2017

- SAE-A Vietnam awarded scholarships to 215 children of our Vietnamese factories employees so that they could attend a local school that was otherwise too expensive for their parents to afford.

Myanmar

- As SAE-A explores opportunities in Myanmar, we are sponsoring two football clubs in Yangon - Konglanghpu FC and Sumbrabum FC. Konglanghpu FC was created by young students studying Christian ministry at Dagon Bible College in a small town near Yangon, and Sumbrabum FC consists of factory workers and students.

Guatemala

- SAE-A Guatemala sends volunteers to the volcano eruption affected region

- The eruption of volcano (thought to be dormant) 40km away from Guatemala factory in the capital of Guatemala occurred on June 2018 resulting in untold damage from the volcano ash falling on the nearby cities of Antigua, Escuintla, and Chimaltenango. Hearing from family, residents and the local media about the seriousness of the damage and the need for aid, the company mobilized a group of company associate volunteers to dispatch to the heart of the disaster area. Volunteers arrived at the region affected and by Volcan de Fuego and began the distribution of emergency supplies, water, foods and engaged in reconstruction efforts.

- Community Support

- Run by a local Guatemalan religious organization, The House of Angels?is a vocational school that provides housing and education for children who are from disadvantaged backgrounds. Members of the Guatemala branch visit the students, donate clothes and support their sewing course.

- SAE-A has also been a part of the Policia Nacional Civil of Guatemala’s Meeting of Families of Heroes, a celebration in honor of the families who had lost loved ones in the line of duty. Taking place around the holidays, SAE-A was honored to give back by donating clothing and gifts for more than 600 children.

Nicaragua

- Tree Planting Campaign held in Tipitapa

- Held every year with support from the Tipitapa City Council, SAE-A’s Nicaragua branch co-sponsors a tree planting campaign at Jose de la Cruz Mena elementary school. Designed to educate children from an early age on the importance of environmental preservation, this campaign gives children the tangible experience of planting trees with their own hands. This year, our Nicaragua branch also donated clothing and ball caps for 150 students. SAE-A has supported the local Tipitapa police. For example, through the donation of computers, the station has improved operational systems and data processing.

Haiti

- Founded the S&H School

- While our business investments create jobs and stimulate markets, we firmly believe that education is critical in ensuring a better life for future generations. In developing the S&H School, the SAE-A Foundation has worked closely with the Government of Haiti, the Korea International Cooperation Agency (KOICA), and local stakeholders to ensure the school meets all requirements and provides an exceptional education to all of its students. In addition to required subject material, the school has a bilingual component for students to learn in English, Haitian Creole, and French, and incorporates the latest technology in its curriculum. We were especially proud that the president of Haiti joined us for the official opening ceremony of the school.

- SAE-A’s Impact

- We employ 11,125 Haitians: 80% have never held a job before nor have they had a stable income; 60% are women; and 631 local employees have already been promoted to administrative /supervisory positions. The average monthly salary is nearly triple the nation’s GDP; 70% of the workers earn more than that. Each employee receives paid vacation, 15 days of sick leave, free transportation, and annual medical screenings. In 2019 we had $178M in exports and we are aiming for $207M for the year 2020. In total, more than 80,000 Haitians benefit from the jobs SAE-A has created. That’s just part of our work. Through our Foundation, we built the S&H School that provides tuition free best-in-class education for 550 students, a number that will grow by about 50 students each year. And students receive hot meals daily. The high school has been completed in 2019 and will be expanded to 700 students. We are committed to doing whatever we can to make the local community a better place.

Focus on Employees

- Indonesia

- Puput Ayu Manggarai

- "My dream is coming to fruition while working for SAE-A"

- I found out about an employment opportunity with SAE-A through a friend of mine back in 2016. I applied, passed the interview process and currently working as an administrative assistant for the finishing team along side a team of colleagues and a supervisor who are like family. Although SAE-A is my second job, I think my career has really made strides because I have been able to learn more than with my first employer.

At SAE-A my salary is better which has improved my quality of life at home. Thanks to the fact that SAE-A is well organized and strict about making sure that work hours and paydays are strictly observed, there is less stress both on and off the job. Since I started working for SAE-A, I have saved enough money to pay for college tuition and I even helped my parents with their home-remodeling.

In the future, it is my dream to study fashion design overseas and someday run my own business, maybe a small scale fashion company or apparel alteration business.

- Guatemala

- Leonarda Enriquez Gomez

- "Ever since I became a mother, I’ve dreamed of sending all three of my children to school"

- I’m so fortunate to have a job at SAE-A. My older sister, Ana, recommended SAE-A to me and now I’m working with her and my younger sister Paula. Paula was the first one to apply for a job at SAE-A because she had heard about its good reputation. When she told me about SAE-A, I decided to apply too. Ever since I became a mother, I’ve dreamed of sending all three of my children to school, and now, with my job at SAE-A, I can. As my husband also works for SAE-A’s fabric factory, we have a double income. We still live in a rented house but, in a few years, we will have enough money saved to buy our own house.

- Vietnam

- Le Duc Tai

- "Thanks to SAE-A, I'm able to support my family."

- I first learned about SAE-A from a friend who was an associate and joined the company in 2015. When I first joined the company, I didn't have any particular skills and could only do very simple tasks. However, after receiving some sewing work training, I became proficient and have improved a great deal. Before joining SAE-A, I worked for a number of companies, but couldn't keep a steady income. But now, I not only have a steady income, but also good benefits from Sae-A, allowing me to support my family. I am very thankful for the opportunity that Sae-A has provided, both to learn new skills and support my family. My dream is to keep working hard for the company, save money, get married, and to keep helping out my parents.

- Nicaragua

- Rosa Amelia Castrillo Gutierrez

- "I’ve learned a lot of things working here"

- SAE-A is the first job I’ve ever had, and I’ve learned a lot of things working here. I never want to get a job at another factory because my colleagues say that no other companies have such a pleasant work environment. By saving money, I was able to purchase some land, and right now we are building a house there. I also receive a bonus every year when renewing my labor contract, and by investing this money, I have begun my own business selling clothes, shoes and accessories on the weekends.

- Haiti

- Joseph Ysenamene

- "Now, I can raise my children on my own without having to borrowing money to get by"

- It was extremely hard to raise my six children without my husband. In the past, I ran a rice stand, but I was not able to earn enough money to support my family. Sometimes I couldn’t pay my bills or I was pickpocketed while traveling here and there to sell rice. One of my friends working at SAE-A recommended the company to me, saying it is very a good workplace. SAE-A has a free shuttle bus for workers and they never force us to work overtime, so I can look after my children after work. Now, I can raise my children on my own without having to borrow money to get by.

Zero Tolerance Policy

- SAE-A believes that our associates are the heart of our business. Their well-being, both at work and home, is of critical importance to the company. Respect is the most basic principle we promote across our entire workforce, from headquaters to factory floors. SAE-A promotes an open work environment, encouraging employees to share ideas for improvement, voice concerns, and maintain an ongoing dialogue fostering a culture of trust.

- SAE-A has a zero-tolerance harassment policy. All employees are informed of the policy and how to raise concerns. All managers attend sexual harassment seminars and together with corporate work to ensure that all of the workers regularly are reminded of their rights and know to report any increase of harassment to a manager and that this communication will remain confidential.

- Health at Work

- For SAE-A, a productive workforce is a healthy workforce. The company provides medical this includes the health of our employees. SAE-A's Guatemala branch provided health education and health screenings to our employees and the spouses of our employees.

- Marcelina Lopez, Guatemala : "At first, I was a little bit nervous to get the screening service because I have never had one before, but I feel so comfortable now after I learned that I am fine. I feel so thankful to the factory for taking a proactive approach to care for our health."Mayra Villalta: "I couldn't imagine that I would get any of medical examinations in my life like this. I am grateful to the factory for providing this screening service to me."

Training and Advancement Programs

SAE-A offers diverse training courses providing our associates with the knowledge and resources necessary for advancing their careers. Classes focus both on skills of importance to an employee’s job at SAE-A, including language classes, but we also, broader professional development courses. SAE-A's Guatemalan branch found many employees were interested in learning computer skills, but few had access to the technology or education. In response to the incredible interest, SAE-A invested in a new computer lab where we hold computer literacy classes for employees and their children.

Edy Fernando, Guatemala :

"Learning how to use computers has been on my wishlist for a very long time. I’d appreciate the company giving me this opportunity."

Delia Joachin, Guatemala :

"I want to learn how to use Excel among other computer programs. I’ll work hard to learn it so that my kids would be proud of me."

SAE-A's Haiti branch holds leadership seminars on a regular basis to equip local workers with the skills necessary to solve problems and improve communication. Understanding that many of the employees in Haiti have never been part of the formal economy, we are committed to helping them improve their skills, many of which can be refined through further on-the-job training positions available to employees. Together, these efforts improve working conditions and prepare local employees to take on leadership roles within SAE-A’s international organization.

Dorainwil Innocent (Cutting Supervisor), Haiti :

"This is a good initiative, I have worked in several companies, but it is the first time I have participated in this kind of event, it helps us to unite more one and other, the chat on the leadership was very positive for me and helped me a lot to lead my group, I hope that this initiative will repeat in the future."

Mendouard Dieuvelt (Packing Supervisor), Haiti :

"I appreciate very much the event, it helped me a lot in my daily work, I learnt how to solve a problem without much complication with my workers, it would be very important to organize this kind of activity every three months."

Pierre Bernard (General Line Supervisor), Haiti :

"It was an excellent idea, all gathered together at the same table to share our joy, food and drink, even though we work in different area but we are all belong to one company, I hope we can continue with this type of activity to achieve together what we want all success"

Workplace Safety

SAE-A strives to provide a safe and comfortable working environment. In each of its facilities the company comply with local and international standards and programs, such as the ILO/IFC Better Work programs and Worldwide Responsible Accredited Production (WRAP). To do this, SAE-A established a company-wide integrated system focusing on industrial safety, occupational health and hygiene programs. The company's industrial Safety and Health Committee focuses on company-wide workplace standards, working with employees to ensure that we hold ourselves to the best practices, and implementing site-specific preventive activities.

SAE-A understands that best practices on paper are one thing, but without regular training they achieve little. That is why it holds regular health and safety training at all of its facilities. Each training is tailored to respect and reflect local laws and regulations, while ensuring compliance with the company's own high standards. Trainings focus on a range of skills including: fire prevention; first aid; personal protective equipment; workplace safety fundamentals; chemical safety; and maternal health and safety.

Environmental Sustainability

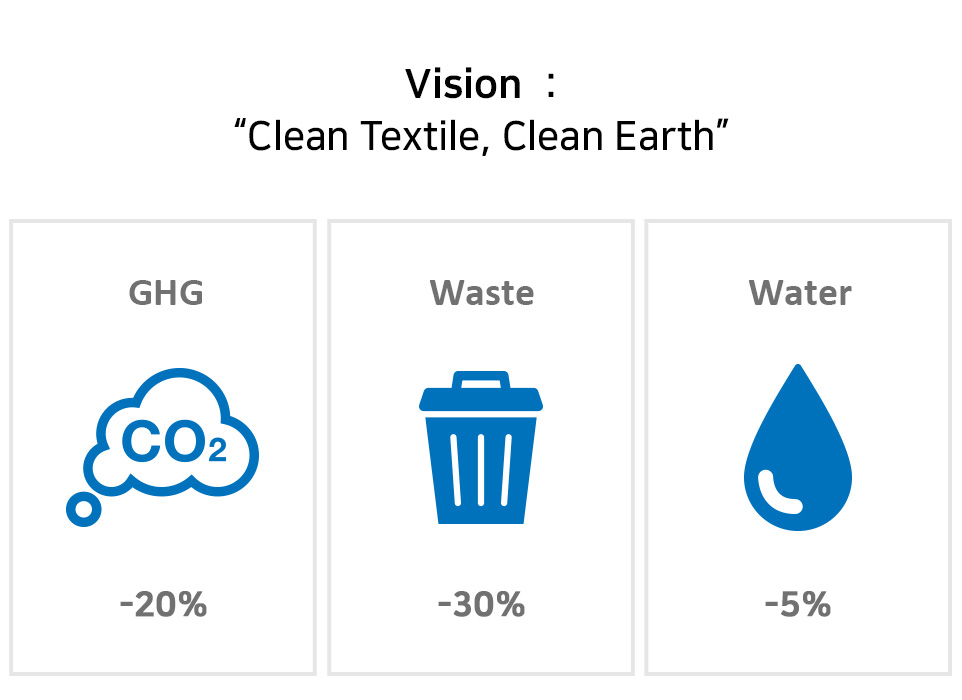

Environmental Sustainability Vision

In the past, Environmental Sustainability might have been a choice in the global industry. However, SAE-A has always been dedicated to understand the significance of Environmental Sustainability and considered as a key factor in our business. Our key focus area includes energy, emissions, waste, and water. Nevertheless, SAE-A constantly explores other fields to make progress in environmental sustainability and achieve corporate responsibility. We have always been dedicated to understand the significance of Environmental Sustainability. Therefore, our goal is to overachieve Environmental Sustainability through practical strategy and innovative technology that positively impacts the global environment.

SAE-A's Environmental Sustainability Policy

- As a forefront company conducting business globally, SAE-A strives to embrace CSR in worldwide environmental issues and attains sustainable development. To be aware of the environmental impact that business activities can put through and to make efforts towards its continuous improvement, we hereby pledge as follows:

-

-

1. Comply with global and local environmental legislations and requirements, and perform environmental management above the level of clients’ expectation.

-

2. Minimize the potential negative effects on environment by confirming and continuous managing EMS (Environmental Management System).

-

3. Comply with global regulations and customers’ requirements on the hazardous substances to provide safe products, and commit to enhance customer values by providing eco-friendly products.

-

4. Contribute to worldwide green growth through eco-friendly production including improvement of Energy use, Greenhouse gas (GHG) emissions, Water use, Wastewater disposal, Air emissions, Waste management and etc.

-

5. SAE-A Trading Co., Ltd. and its partner companies plan and conduct business activities under the consideration of environmental issues, and raise awareness of environment among executives and staff members through continuous trainings.

-

- As a result, we aim to provide information of the environmental performance to customers and stakeholders on a regular basis.

Environmental Sustainability Board and Organization

In 2008, SAE-A’s Board of Directors established a dedicated Sustainability Board, a frontier among Korean apparel manufacturers. The Board advises on the creation and execution of company-wide strategy to advance SAE-A’s sustainable management practices. The Sustainability Board also created a cohesive whole-of-company Environmental Management System across all branches and facilities to promote eco-friendly production. In order to ensure SAE-A is sensitive to the different environments in which it works, regional committees report to the Sustainability Board regularly. The Sustainability Board holds seminars for employees and partners, across our operations and locations, providing basic information and updates to employees and partners about pressing environmental issues as well as ensuring full compliance with both the government regulations and our policy.

In 2009, SAE-A established a sustainability team that specializes in environmental management and chemical safety regulations. Following the foundation of the SAE-A sustainability team, long-term environmental management strategies were established, and we have been continuously striving to achieve a leading position as an environmental-friendly textile vendor. SAE-A has set up a new environmental targets for each of the categories, based on our database system.

SAE-A has been releasing annual Sustainability reports which introduce economic performance, quality assurance, compliance, social responsibility, and environmental management activities since 2013.

Environmental Sustainability Goal by 2030

*Normalized target with a baseline year of 2017

*Normalized target with a baseline year of 2017

Energy and GHG

- Energy Diagnosis Project

- Under the supervision of the Ministry of Trade, Industry, and Energy, SAE-A has assessed its energy usage and presented plans for improvement in collaboration with seventeen business partners. Numerous measuring devices were used to achieve reliable measurements, including electric power analyzer, illuminometer, thermographic camera, and combustion gas analyzers. Unnecessary energy loss was reduced by applying the optimal plans for energy efficiency improvements to the entire factory.

- Energy and GHG Management

- Since 2013, each factory managed its energy usage by an internal tool to identify the status of energy use in the overseas subsidiaries and subcontractors. Based on this tool, a greenhouse gas inventory system has been built to regularly analyze energy usage by monitoring greenhouse gas emissions. Moreover, an energy was diagnized by a specialized consulting firm to accurately identify and resolve issues. Energy diagnosis improved energy efficiency by changing the operation method of the existing facilities or replacing them with highly efficient facilities. Eco-friendly facilities have been prepared to save energy and reduce greenhouse gas to the maximum extent possible.

- Energy and GHG Monitoring System

-

SAE-A has built a monitoring system for greenhouse gas emissions to collect the monthly energy usage data of all overseas subsidiaries. In addition, an energy usage of stationary combustible facilities such as boilers and emergency generators, mobile combustible facilities such as vehicles owned by the branches, all other electricity usages are checked to prepare analytical reports for each quarter in order to identify the energy usage trend in each subsidiary.

In addition, an independent greenhouse gas inventory has been built to check greenhouse emissions from stationary combustible facilities, mobile combustible facilities, electrical facilities, and some fugitive emission facilities such as refrigerant of air conditioners and CO2 extinguishers. SAE-A’s greenhouse gas inventory was designed based on the Korean operation guideline of greenhouse energy goals and management, and it consists of two steps: diagnosis and calculation. First, the diagnosis step involves identifying the sources of energy and greenhouse gas emission through on-site investigation by an expert and defining the methodologies for emission calculation by setting the boundary between business organization and operation. Afterward, in the calculation step, the greenhouse gas emission is calculated through active data collection from the site and selection of emission factors and approaching techniques. Emission factors followed the IPCC Guideline which is an international greenhouse gas guideline, and nation-specific emission factors are used as references for electricity usage which belongs to indirect emission. The precision and reliability of the inventory have been verified by a professional examiner.

Waste

- Waste and Recycling Management

- The developing countries where SAE-A’s production factories are located are inadequately equipped with essential infrastructure for waste management, as their standards and local environmental laws are relatively simple compared to developed countries. SAE-A requires strict compliance with national environmental laws and thorough waste management by the environmental managers in the factory, as part of its effort to reduce the amounts of general and harmful wastes and increase the recycling ratio.

- Waste Generation Monitoring System

- For thorough management, SAE-A has established an inventory that subdivides the types of waste in order to measure the waste amounts every month and delivers the invoice details from the collector to the Sustainability team in the headquarters to analyze the waste and recycling amounts.

- Waste Recycle

- Some factories in SAE-A have replaced the older fossil fuel boilers with exclusive incinerating boilers for fiber to recycle waste as fuel for boilers. Fiber waste made of 100% cotton is used as energy under the authorization of the national government. As fiber waste can be recycled as a substitute for fossil fuel, the overall amount of waste has decreased.

Water

- Water Quality Management

-

SAE-A owns a Waste Water Treatment (WWT) system in the factory where our wet processes take place, including washing and fabric production. Through thorough management, SAE-A ensures that all local environmental laws are strictly observed, in all factories.

For the installation of counters that is essential to identify the amount of wastewater, the Sustainability team in the headquarters delivers necessary information to each production base. Calibration of the installed counters is compulsory. Also, the quality test of wastewater is conducted regularly (by a third party or internally) in compliance with the local regulations in the region where the production base is located.

PT.WINTEXTILE in Indonesia has been known for its efforts in environmental management, as its own waste water treatment is recognized as the best in western Java by the Ministry of Environment in Indonesia. Its waste water treatment, which minimizes chemical use by employing bacteria, is recognized as an exemplary model of eco-friendly waste water treatment.

- Water Reduction

- SAE-A promotes water saving through regular training sessions and campaigns. At these training sessions, a guest speaker or the environmental director of the branch will take the podium. As a result of these training sessions, eco-friendly campaigns such as ‘personal tumbler use’ or ‘tepid water use’ are underway in many branches. As well, other efforts such as regular pipe maintenance, installation of rainwater tanks, and reduction of the hydraulic pressure in water tanks are in progress.

- Water Recycle

- In order to ensure optimal working conditions, SAE-A uses a cooling system that leverages green technology. This system allows factories to maintain room temperature by pumping water through a porous ventilation wall on one side of the factory. As air passes through that ventilation wall, the water evaporates, cooling the air and increasing circulation. This passive cooling technology offers remarkable results while energy saving and reducing carbon emissions. SAE-A is currently exploring the potential of installing this system in even more factories all around the world.

Environmentally Sustainable facilities

- Changing the Operation Type of Air Compressor

- Efficiency can be maximized and electricity consumption can be minimized by changing the operation method of the compressor from the soft type, in which 100% of the electricity has to be consumed, into the inverter type.

- Replacement and Installation of Lighting Facilities

- The mercury lamps were replaced with more energy-efficient five-wavelength fluorescent lamps, reducing power consumption from 300W to 85W. A daylighting has also been installed to minimize power consumption during the day. In addition, all factories use LED lighting, which uses less electricity than fluorescent light.

- Installation of Water Cooling Pad

-

A water cooling pad is an eco-friendly facility that can reduce the indoor temperature by 3-5 degrees Celsius while using less energy than an air conditioner. To install a water cooling pad, a water pad from which water flows is installed on one side of the wall in the factory and a fan system is installed on the other side. When operated after installation, the water flowing from the water pad comes into contact with the air from the fan, and a large amount of air flows into the water pad. In this way, the air that passes through the water pad reaches a relatively lower temperature and circulates in the factory to keep the indoor temperature low, with less energy cost than an air conditioner.

- Installation of Electricity Condenser and Inverter

-

Installation of electricity condenser and inverter in Sae-A Spinning leads to a great amount of electricity savings. Installation of low pressure phase condenser improved power factor from 0.94 to 0.97 which decreased energy loss. Moreover, inverter installation saved about 8,640 kwh of electricity per month by minimizing electricity loss and maximizing efficiency.

[Installation of Electricity Condenser and Inverter]

[Installation of Electricity Condenser and Inverter] - Installation of a Waste Heat Recovery Unit

- Waste heat recovery is a system that supplies and recycles the waste heat from factory processes back into the factory to reduce energy usage. A waste heat recovery unit saves energy, as the heat from the boiler pipe and steam pipe are recycled in the factory where the ironing process is required. It is clear that boilers operate more efficiently with a waste heat recovery unit that reuses waste heat.

- Replacement of ODS (Ozone Depleting Substances) Refrigerant

- ODS is prohibited in most industrialized countries but are still used in developing countries as a refrigerant for air conditioners. Despite the fact that most of our locations are in developing countries, SAE-A has replaced the refrigerant for air conditioners with an air ratio substitute of R410A or others.

Chemical Management

- Sae-A established its chemical management system through environmental data collection for each quarter. We have managed information on the chemicals used in our factories including the name of the product, MSDS number, chemical ingredient, and CAS number. Moreover, there are about twenty sections for product categorization which efficiently manage chemicals used in our factories.

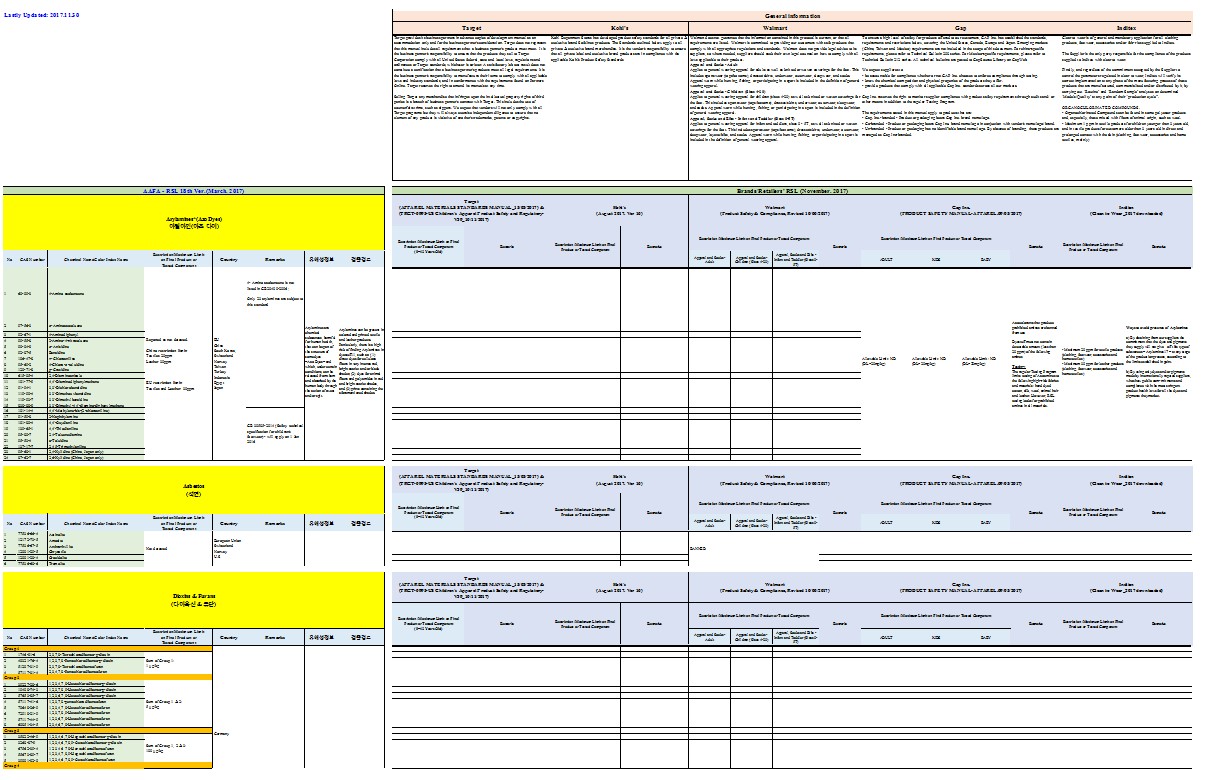

- Establishment of the SAE-A Restricted Substances List (RSL) Library

-

To ensure product safety by eliminating harmful substances, SAE-A analyzes the manuals of customer companies based on the Restricted Substance List (RSL) from the American Apparel & Footwear Association (AAFA), which collects and publishes the regulations on textile products in the major countries, to build an independent integrated RSL Library. SAE-A is making every effort to fulfill not only the regulations of each country in which it operates and the requirements of customer companies, but also to ensure product safety for final customers with the RSL Library.

Sae-A RSL Library

닫기

닫기 - Establishment of the IT (S.H.I.E.L.D.) System for Hazardous Substances

-

SAE-A created its own IT system, known as S.H.I.E.L.D. (Sustainability System for Highly Integrated Environmental Laws Database), to protect end users from harmful substances. Moreover, it fosters sustainable management, as it abides by the safety requirements for products from North American buyers. SAE-A upgraded the S.H.I.E.L.D. system to regularly collect 66 CHCC (Chemicals of High Concern to Children) test reports or similar documents from supply chains to cope with various U.S. state laws. This system was developed from a pilot test that was conducted in cooperation with subcontractors, as it may be easy for them to use it in the long-term storage of necessary technological documents, as well as to search for those documents using real-time access

Sae-A S.H.I.E.L.D. System

닫기

닫기 - ZDHC

-

ZDHC is a program by Greenpeace to achieve Zero Discharge of Hazardous Chemicals by 2020. Eliminate the use of hazardous chemicals by focusing on MRSL (Manufacturing Restricted Substances List), Conformity Guidance, Wastewater Quality, Audit Protocol, Research, Data and Disclosure, and Training. Sae-A are conducting ZDHC training to suppliers and factories regularly and monitoring ZDHC test result of facilities for hazardous chemical management.

The ZDHC Programme & Tools

https://www.roadmaptozero.com/programme/

Eco Certification